Industry Sharing Tips From Aluminium Profile Manufacturing

- By:Naview

- Date:2022-02-17

There are many aluminium profile manufacturers on the market across the country, the industry aluminium profile manufacturing market is booming, and many brands are rising. Aluminium is a product made from aluminum and other alloying elements. The main metal element is aluminum, and some alloying elements are added to improve the performance of aluminum.

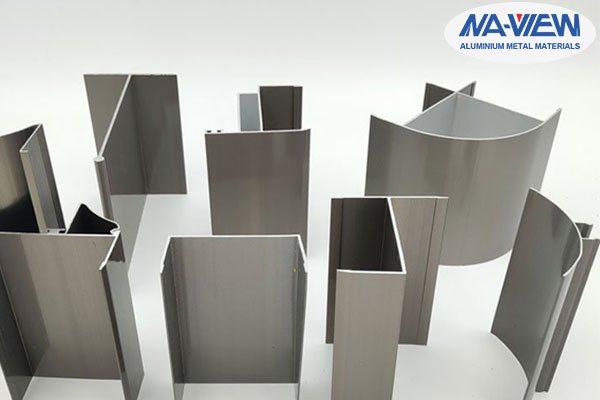

NAVIEW ALUMIUIUM manufacturer, specializing in the production of architectural aluminium profiles, industrial aluminium profiles, special-shaped aluminium profiles, aluminium alloy profiles, door and window aluminium profiles, aluminium formwork, curtain wall aluminium profiles, kitchen cabinet aluminuim profiles, wardrobe aluminium profiles, and decoration Aluminium profiles, etc.

From mold development and design to industrial aluminum extrusion production, and subsequent deep processing of aluminum profiles state. It can be processed into aluminium alloys of various shapes and specifications. Mainly used in the manufacture of aviation equipment, daily necessities, doors and windows for construction, etc. Deformed aluminium alloys are further divided into non-heat-treatable-strengthened aluminum alloys and heat-treatable-strengthened aluminium alloys.

The non-heat-treatable-enhanced type cannot improve mechanical properties through heat treatment, but can only be strengthened through cold working deformation. It mainly includes high-purity aluminum, industrial high-purity aluminum, industrial aluminum, and rust-proof aluminum. Heat-treatable-strengthened aluminium alloys can improve their mechanical properties through heat treatment such as quenching and aging. They can be divided into hard aluminium, forged aluminium, super-hard aluminium, and special aluminium alloys. Cast aluminum alloys can be divided into aluminium-silicon alloys, aluminium-copper alloys, aluminium-magnesium alloys, and aluminium-zinc alloys according to their chemical composition.

In any case, the choice of metal is based on its mechanical properties, physical and chemical properties, and price. Therefore, the three major properties of aluminium and aluminium alloys make them widely used: 1. Lightweight (its specific gravity is about 2.7); 2. High mechanical strength can be obtained after proper alloying and heat treatment; 3. Pure and pure Good corrosion resistance of metals. Aluminium and aluminium alloys also have excellent thermal conductivity, electrical conductivity, and reflectivity; their ductility is strong and the processing cost is low; due to their non-magnetic, high waste recycling value, and its non-toxic and colorless corrosion products, It can be widely used in chemical and food industries.

At the same time, aluminum can obtain other superior properties after different treatments. Therefore, the selection must be considered from an economic point of view. For example, the strength requirements should be considered together with lighter weight and good corrosion resistance. In addition to satisfying the mechanical properties, the selection of a special alloy still needs to consider the process method and use conditions. Among so many metals, aluminum and aluminum alloys meet the performance requirements of most industries. However, aluminum alloy materials have low hardness and poor wear resistance and wear and tear often occurs.

CONTACT US

Foshan Naview New Building Materials Co., Ltd.

We are always here offering customers our reliable products and service.

If you want to liaise with us now, please click contact us